Published 17.11.2016

Products

Products

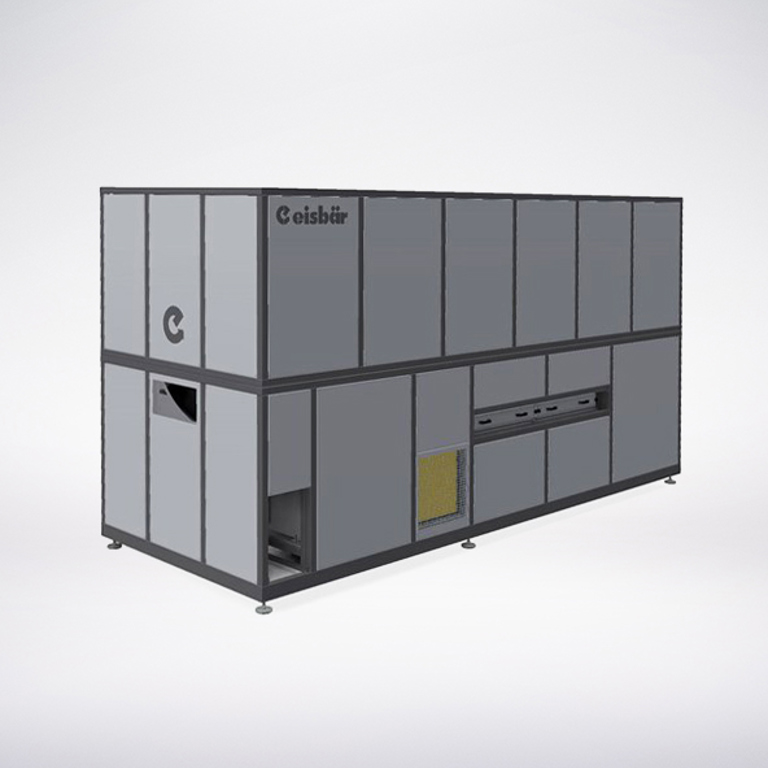

Temperature conditioning system TS 30

Special system for temperature conditioning and cooling plastic parts

The temperature conditioning system TS30 from Eisbär is designed for the controlled temperature conditioning and cooling of plastic parts immediately after the injection-molding process. The parts enter the rotating heating and cooling drum via an inlet chute and are conveyed to the outlet hopper in a controlled manner by the system.

The path through the system is divided into the following sections:

- Heating

- Temperature conditioning

- Thermal decoupling

- Cooling

Advantages:

- Max. 30,000 parts per hour

- No pressure marks

- Production parts only come into contact with stainless steel.