- Home EN

- Plastics industry

- Exhaust air cleaning ACF30-System

Effective exhaust air cleaning with the

ACF30 System

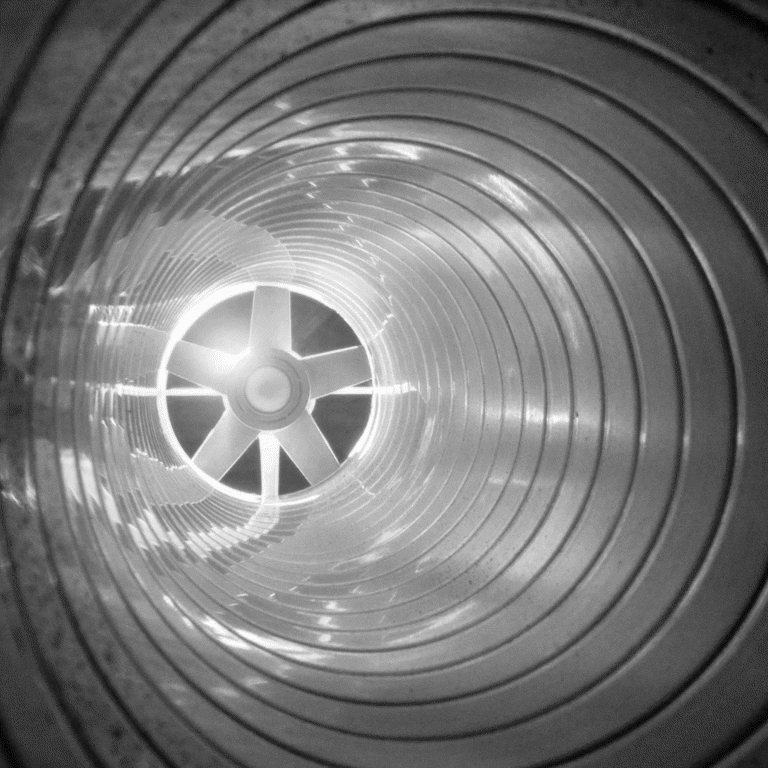

The ACF30 exhaust air cleaning system operates with an innovative three-stage cleaning process that ensures maximum efficiency and sustainability in the recycling process:

- Fine dust filter (Class M5):

In the first stage, solid particles are removed from the exhaust air. The fine dust filter ensures that even the smallest particles are reliably separated. - Condensate separator with heat exchanger:

In the second stage, the exhaust air passes through a condensate separator. Using a heat exchanger, all condensates just above the cooling water temperature (2–3 °C) are efficiently filtered out. - Activated carbon bed:

The third and final stage uses an activated carbon bed, which removes almost all remaining pollutants from the exhaust air. Only a few aerosols, as described in the literature, are excluded.

PERFECT FOR THE RECYCLING PROCESS

The three-stage design of the ACF30 guarantees high cleaning performance, making it an ideal solution for recycling plants where clean exhaust air is a crucial factor.

Gallery